Our experts can work with you to solve specific issues around production, layout, visual management and delivery

Process mapping is an in-depth, visual way to identify the steps of a process and the way it is actually carried out.

As part of process mapping, we will teach you the methodology of process mapping, including SIPOC, and facilitate a session with your people. At the end of our engagement you will have a clear map and understanding of your process and actions to address the issues identified.

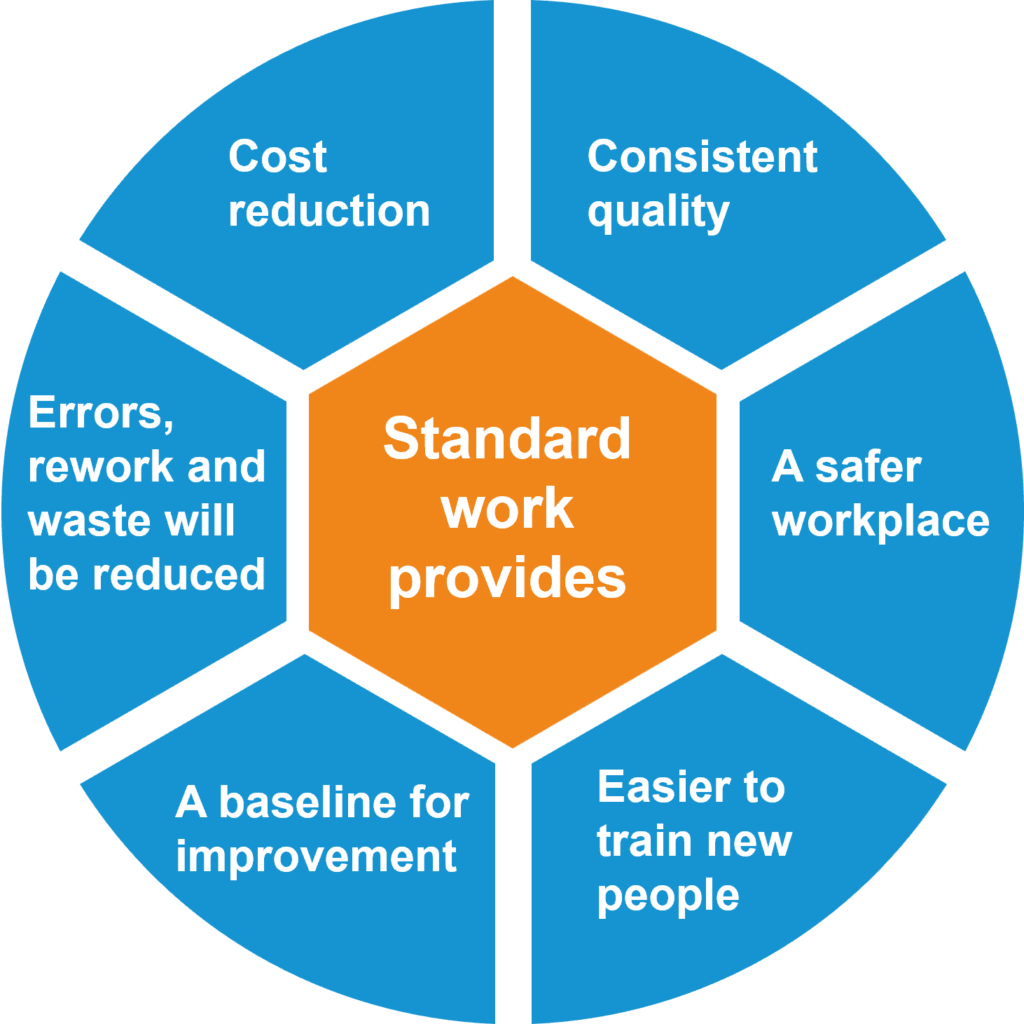

Standard work is part of good business practices and is the most efficient and safe way to perform work and leads to the highest quality, the best service for customers and at the lowest cost. It produces correct and consistent results across the organisation leading to less errors and fire-fighting.

How can we help with standard work practices:

A 5S workplace is easier for people to navigate, find what they need and identify problems faster.

We can assist in training your people in the 5S of sort, set, shine, standardise and sustain and lead a 5S campaign on site. We will leave you with the tools to help sustain 5S with visual standards, audit sheets and 5S boards.

Team Boards, KPI Boards, Information Centres, etc. utilise Visual Management to:

We will work with you to identify the information needed, build the boards and coach your leaders and supervisors on daily meetings/tool box.

Organisations that have evolved and grown over time, usually build processes based on bolting on new services or production lines. We will work with you to understand your current vs future state needs and use tools such as spaghetti diagrams and process mapping to:

We will then work with you to apply the layout changes and coach to improved standard work.

Optimise Workplace Efficiency with CI Team’s Time in Motion Study Approach